Understanding Pearlescent Pigment Powder

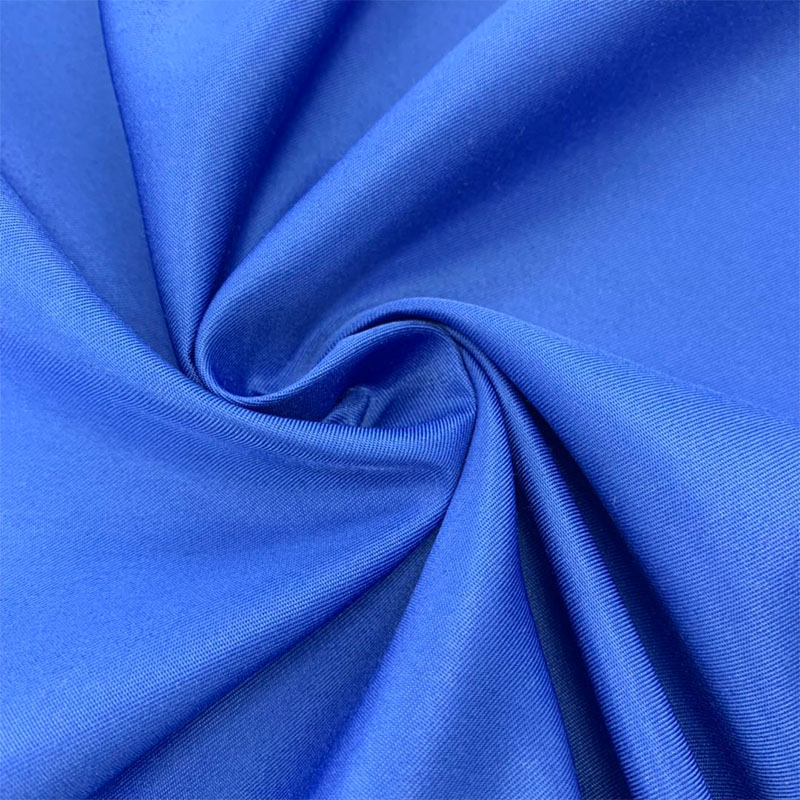

Pearlescent pigment powder is a specialized type of pigment renowned for its iridescent shimmer and luminous qualities. It is available in a spectrum of colors, with silver and gold being the most common choices for Polyester Pearly Printing Fabric. The unique characteristic of pearlescent pigment powder lies in its ability to reflect and refract light, creating a mesmerizing sheen on fabrics.

The Printing Process Unveiled

Preparation of Printing Color Base: The journey begins with the meticulous preparation of the printing color base. This base serves as the canvas upon which the brilliance of pearlescent pigment powder will be unveiled. A carefully curated mixture of pigments, binders, and additives forms the foundation of this color base.

Integration of Pearlescent Pigment Powder: The pivotal moment arrives as pearlescent pigment powder is introduced into the printing color base. This step requires precision and expertise to achieve the desired level of sparkle and luminosity. The amount of pigment powder added is adjusted to meet the envisioned aesthetic of the Polyester Pearly Printing Fabric.

Homogenization and Dispersion: The amalgamation of pearlescent pigment powder with the printing color base is a harmonious process aimed at ensuring uniformity and consistency. Thorough mixing and dispersion techniques are employed to evenly distribute the luminous particles throughout the base.

Embarking on the Printing Journey: With the color base infused with pearlescent pigment powder, the fabric printing journey commences. Various printing methods, such as screen printing or digital printing, are employed to transfer the exquisite design onto the polyester fabric. Each pass through the printing equipment contributes to the creation of a radiant and captivating pattern.

Curing and Fixation: Post-printing, the Polyester Pearly Printing Fabric undergoes a crucial curing or fixation process. This step is essential for setting the pearlescent pigment particles onto the fabric fibers, ensuring enduring brilliance and colorfastness. The meticulous curing process elevates the fabric's durability and longevity.

The Enchantment Unveiled

The culmination of these intricate steps results in Polyester Pearly Printing Fabric that captivates with its luxurious sparkle, opulent shimmer, and dynamic visual depth. The artistry of pearlescent pigment powder infuses life into textiles, transforming them into exquisite masterpieces that transcend mere functionality.

Applications and Appreciation

Polyester Pearly Printing Fabric finds admiration and utilization across diverse domains, from high-fashion apparel to interior décor and beyond. Its allure extends to enthusiasts and connoisseurs seeking textiles that blend aesthetic allure with practicality seamlessly.

English

English Español

Español

.jpg)