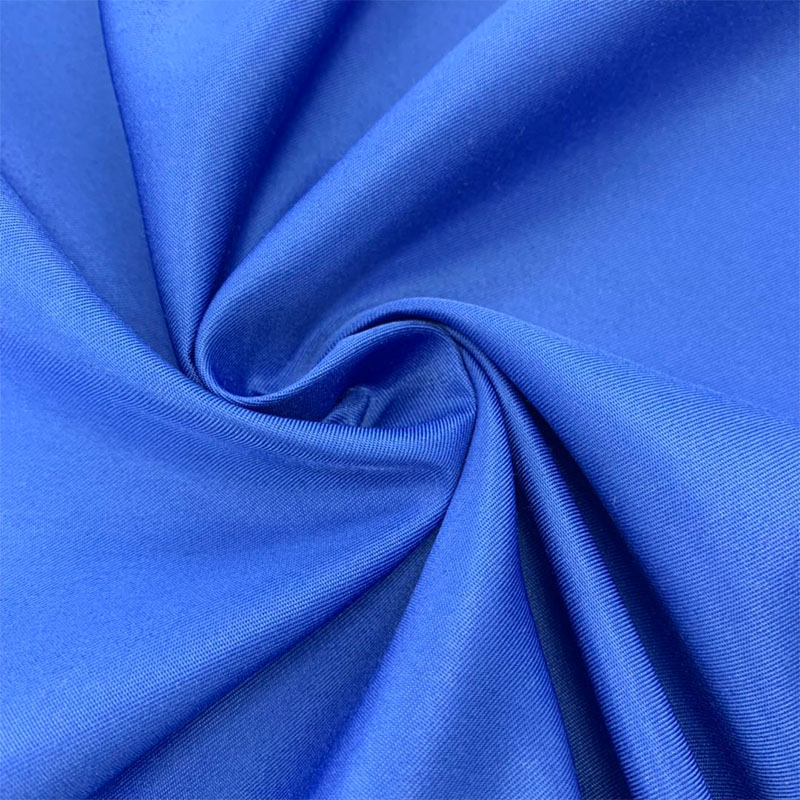

Polyester is a synthetic fiber known for its durability, resistance to wrinkles, and vibrant color retention. However, its synthetic nature also means that it requires specific types of dyes known as disperse dyes. These dyes are designed to bond with synthetic fibers like polyester, ensuring long-lasting and vibrant colors.

When contemplating multiple dyeing sessions for polyester fabric, it's crucial to ensure that the dyes used are compatible with polyester. Using the wrong type of dye can result in poor color uptake, uneven coloring, or damage to the fabric.

Factors to Consider When Dyeing Polyester Fabric Multiple Times

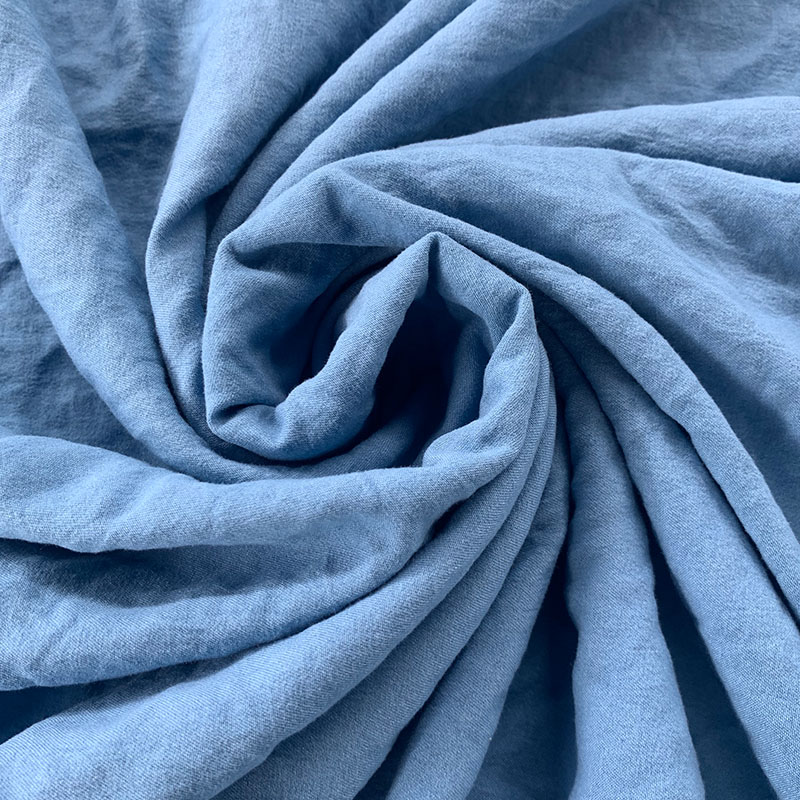

Fabric Integrity: Polyester fabric can be sensitive to high temperatures, especially during dyeing processes. Repeated exposure to heat can potentially affect the fabric's integrity, leading to issues such as shrinkage or texture changes. It's essential to follow the manufacturer's guidelines regarding dyeing temperature and duration to minimize the risk of damage.

Color Depth: Achieving a darker color through multiple dyeing sessions depends on several factors, including the initial color of the Dyeing polyester fabric, the concentration of dye used, and the dyeing technique employed. It's important to conduct tests on a small area of the fabric to gauge how much darker the color can become with each additional dyeing session.

Dyeing Techniques: Different dyeing techniques, such as immersion dyeing, tie-dyeing, or gradient dyeing, can yield varying results in terms of color depth and intensity. Experimenting with different techniques can help you achieve the desired darker color while adding unique patterns or effects to the fabric.

Consistency and Monitoring: To ensure uniform coloration and avoid color discrepancies, maintain consistency in dye concentrations, immersion times, and agitation levels during each dyeing session. Regularly monitor the fabric's color during the dyeing process to assess the desired level of darkness.

Tips for Successful Dyeing Sessions

Use high-quality disperse dyes specifically formulated for polyester fabric.

Follow the dye manufacturer's instructions meticulously, including dyeing temperature, duration, and any additional steps like using fixatives or setting agents.

Test the dyeing process on a small, inconspicuous area of the fabric before proceeding with multiple dyeing sessions.

Keep detailed records of dye concentrations, process times, and any adjustments made during each dyeing session for future reference.

Consider alternative dyeing techniques or pre-dyed base fabrics to achieve darker colors without excessive dyeing sessions.

English

English Español

Español

.jpg)